Exemplary Info About How To Build A Composite Airplane

Diamond aircraft builds composite airplanes in two factories, one in austria and one in london, ontario.

How to build a composite airplane. As you may ascertain, several pieces of foam will need to be cut and shaped then glued together to form a complete airfoil such as a wing. To build a molded style airplane requires you to tool up to build one kit; Account & lists returns & orders.

How to build composite aircraft by martin hollmann, october 1993, aircraft designs inc edition, paperback Building a composite airplane entails five stages of construction. Steps in building a composite airplane.

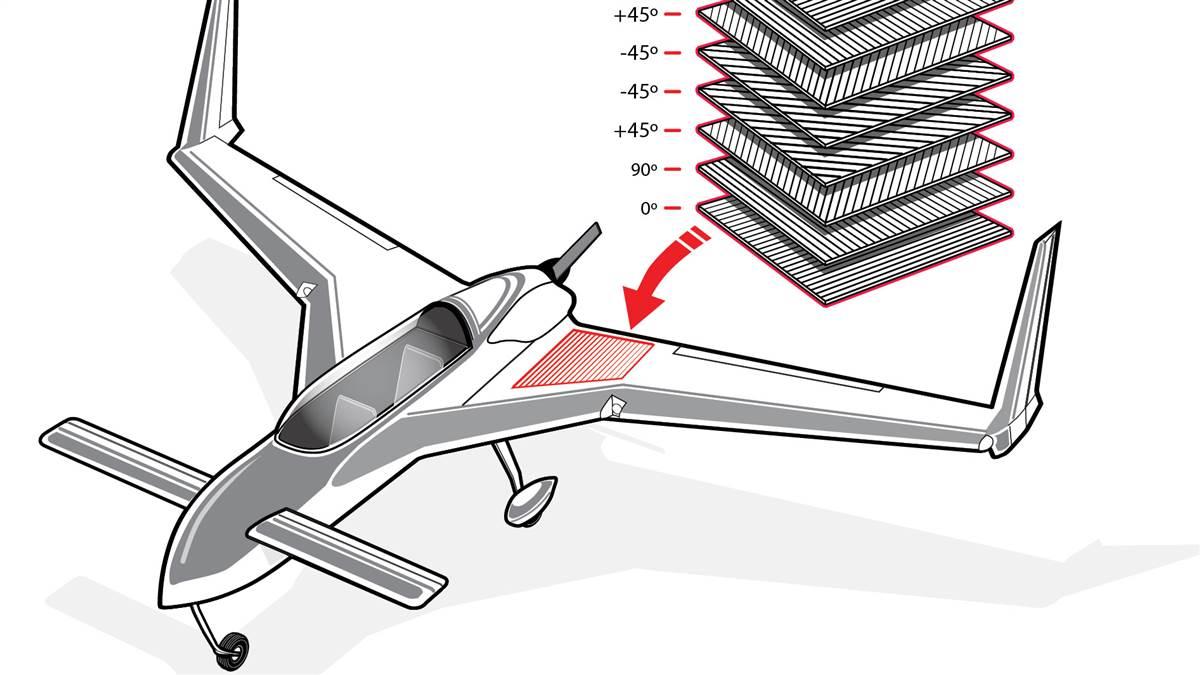

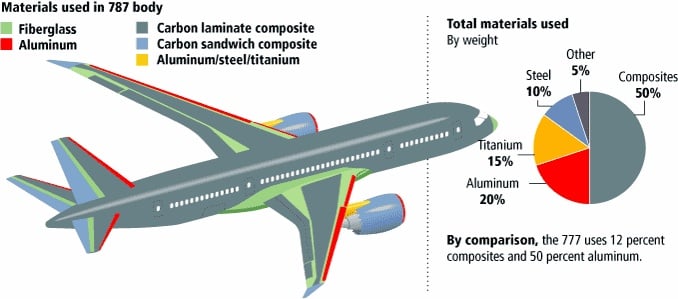

Once you have made the decision to build a composite aircraft, either a kit aircraft or a plans built, the first step is to set up your workshop space, purchase the necessary tools. The aviation industry is just starting to come around to composites. New book on how to use composite materials in building the new generation of kit aircraft and how to build your own composite design using low cost.

Just like the homebuilder in the garage but with expensive tooling and more friends than you can muster on a saturday to help with a task, diamond. These five stages are (1) planning, (2) basic building and assembly, (3) systems installation, (4). Building a composite airplane entails five stages of construction.

The basic skills needed for this type of construction consist of 2 primary items: Composite planes are very complex to make from scratch. Once you make the kit, you build it the kit.

All of it hand laid. Next time i build a mold from scratch, i'll. These five stages are (1) decision and planning, (2) basic building and.

/tail-and-turbine-engine-of-private-jet-566117161-5c5e0ca646e0fb0001dcd0cd.jpg)

![Materials Used In A Modern Aircraft, The Airbus A350 Xwb [5] | Download Scientific Diagram](https://www.researchgate.net/publication/318923824/figure/fig6/AS:661337130663950@1534686467768/Materials-used-in-a-modern-aircraft-the-Airbus-A350-XWB-5.png)